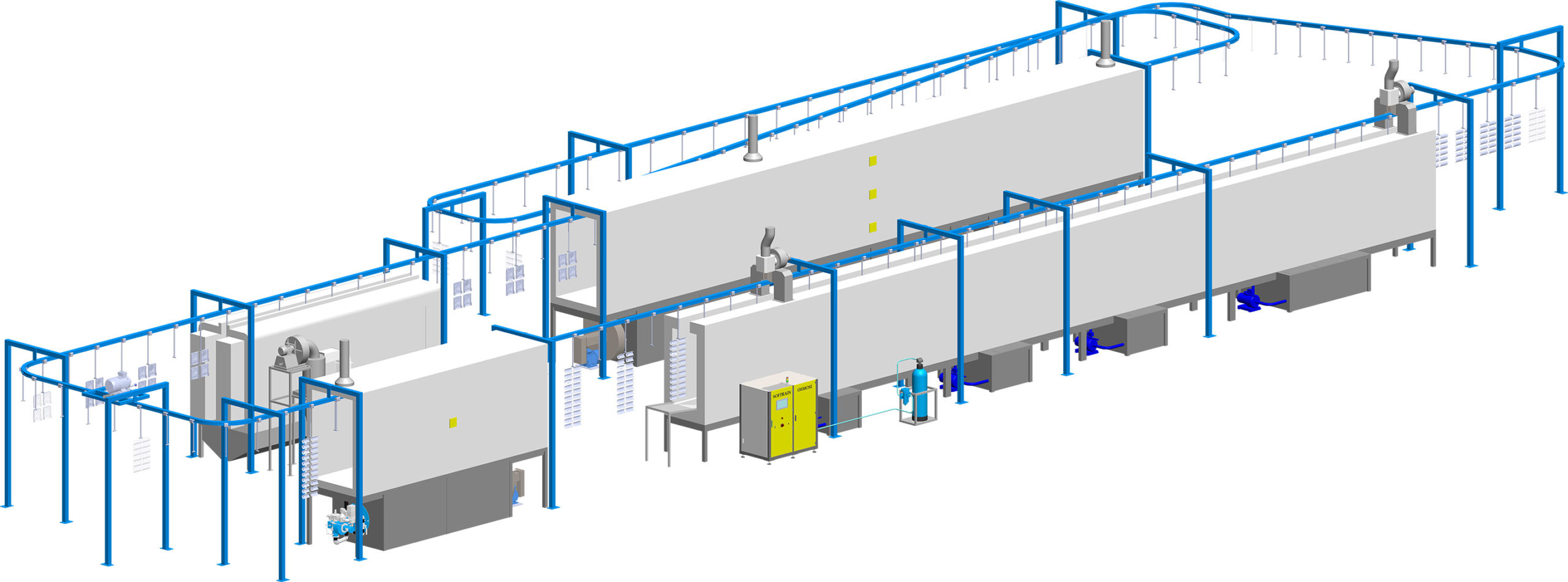

Soft Rain Osmosi HE 1000

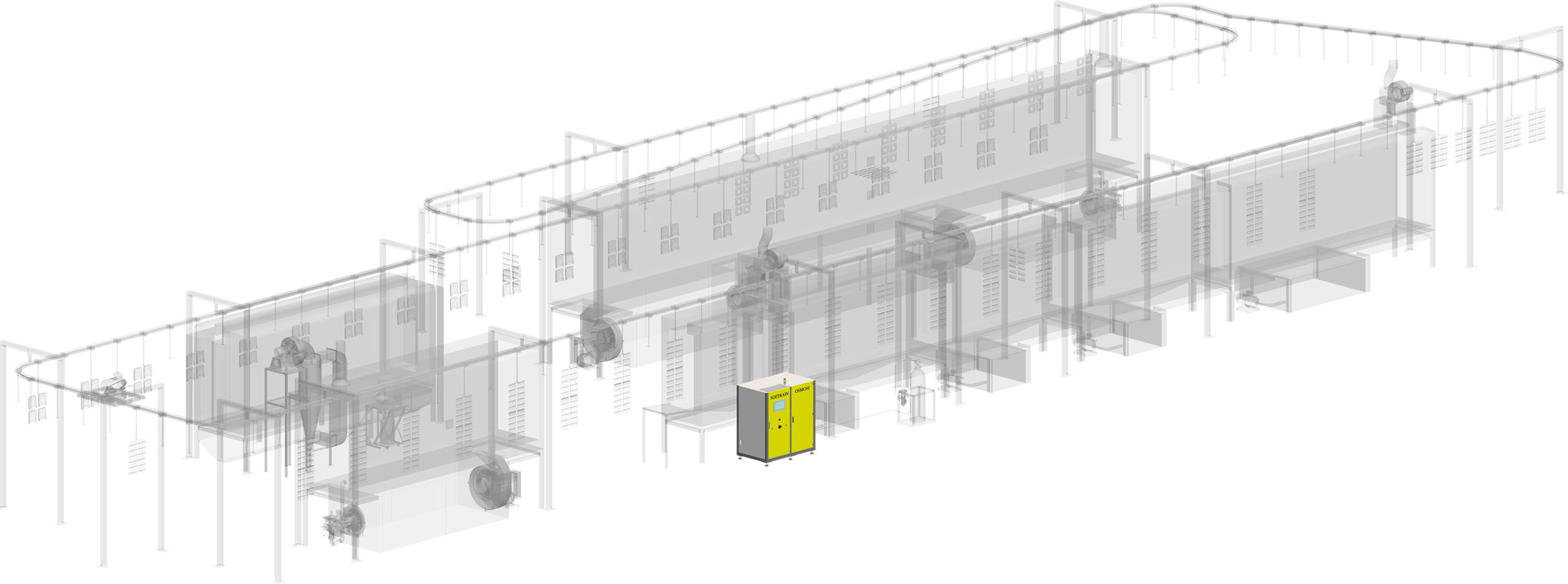

Water with adequate characteristics allows to improve the adhesion and corrosion resistance performance of the painted product, therefore it is a priority to have the electrical conductivity and pH values of the water produced constantly under control. Our system will be the only power source for the pretreatment tunnel.

The Osmosi HE 1000 system provides upstream a specific water pre-treatment system which in turn will feed the reverse osmosis system which can be equipped with a series of accessories to improve the characteristics of the solution to be used.

Insights into the technologies present as standard in the Soft Rain Osmosi HE 1000

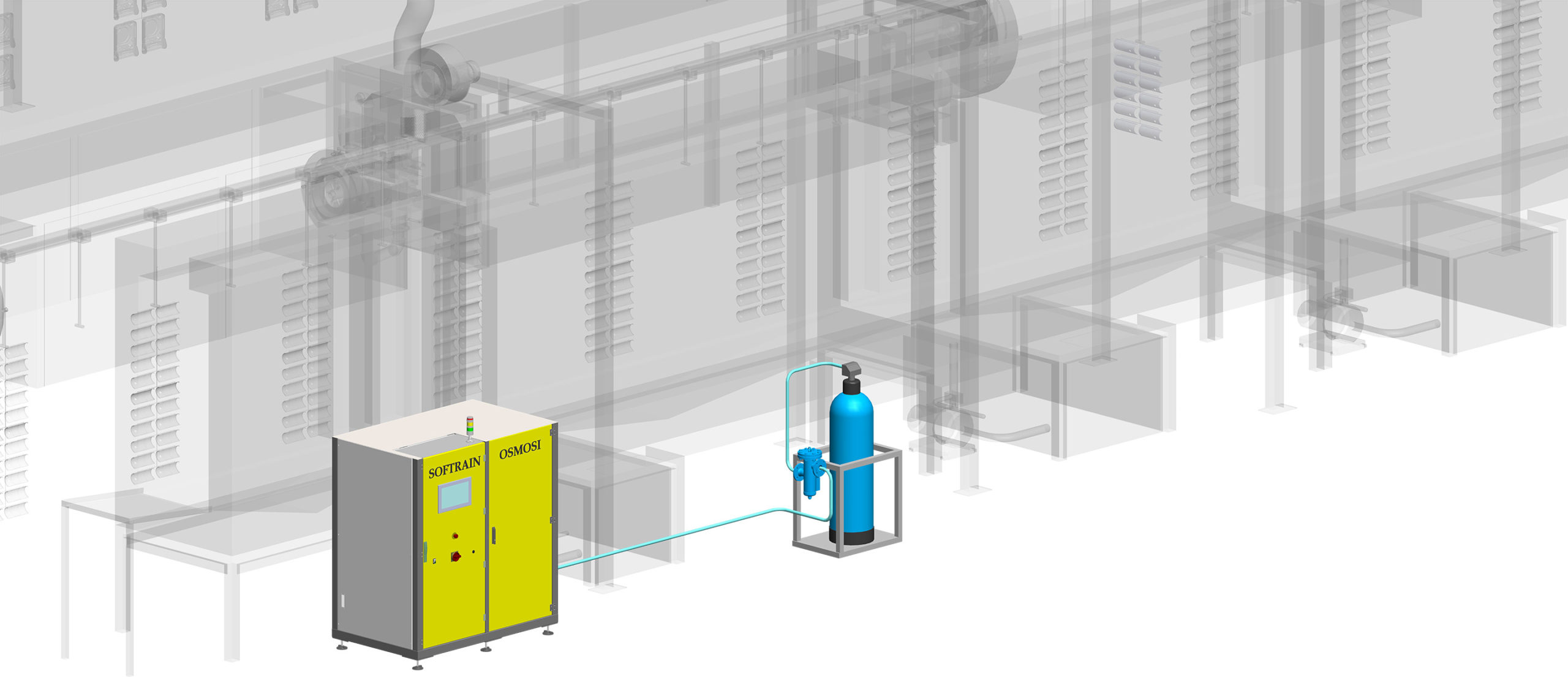

Pre-treatment of the water, using mineral coals and with a mechanical pre-filtration, essential to use our reverse osmosis system considering mains water coming from the water supply.

Our pre-treatment is analyzed, studied and designed according to the type and mineral characteristics of the water to be used to power any Soft Rain system or device.

We are able to provide incoming water treatments with column filtration of different types. Special skids (stainless steel structures) are created for these devices, and the systems are also equipped with automatic control units for backwashing the minerals or resins used.

Reverse osmosis has been designed and built specifically for use on painting lines with high performance and high reliability.

The efficiency is 70%, it produces 1000 l / h of permeate (osmotic water) and produces a concentrate (waste) equal to 400 l / h. This ratio remains unchanged regardless of the external operating temperatures because an elaborate software combined with a specific hardware manage all the phases appropriately to obtain this result. The premixing of the antiscalant product the system is supplied with guarantees long life for the osmotic membranes because it is dosed at regular intervals at a very low concentration.

The system also includes a storage tank with an elaborate recirculation system that passes through a UV-C lamp device with the aim of constantly limiting bacterial loads.

Osmotic water produced will change into osmotic solution because the alkalizing solution is injected in it.

Considering the dusty environments in which the equipment is installed, the central unit was conceived and designed to contain all the components inside and keep them intact.

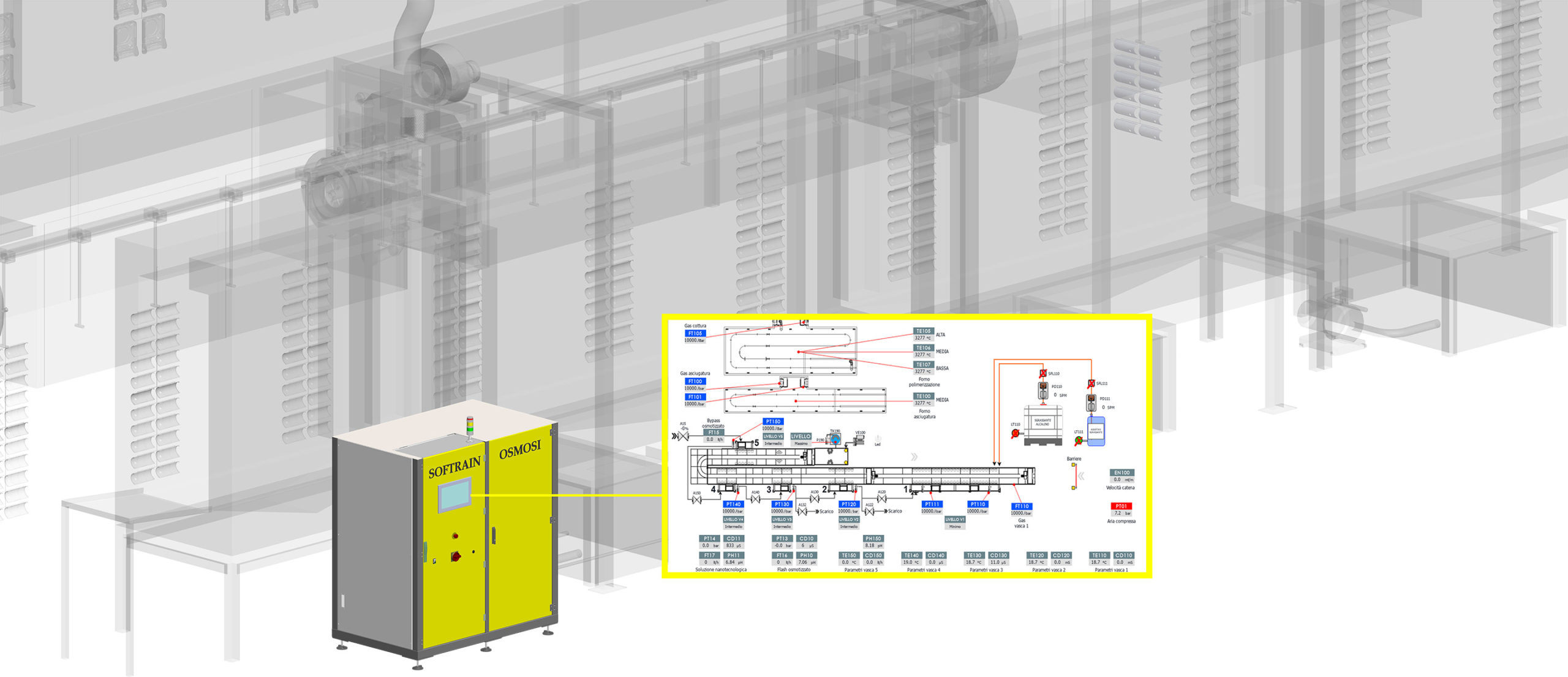

The central unit was designed by dividing the system into different operating areas and each one groups together the components inherent to the technology applied in it.

Electric area:

Touchscreen, simple and intuitive operator panel, in colors of 10 “, 15.6” and 17 “.

Switch emergency mushroom pushbutton for immediate stop of all activities controlled by the system.

Electrical panel with PLC, low voltage power supply and all control and management interfaces.

Electrochemical Analyzers.

Hydraulic and pneumatic areas:

Hydraulic circuit equipped with: high pressure hydraulic pumps, manual and electrically motorized valves, different types of filters, pressure regulators, flow sensors, probes, etc …

Osmotic water storage tank.

The pneumatic system is equipped with a filtering unit for the machine inlet air and uses a series of solenoid valves to drive pneumatic actuators.

All device materials are compatible with the solutions, such as PVC, PP, PVDF, PTFE, 304 and 316 stainless steel

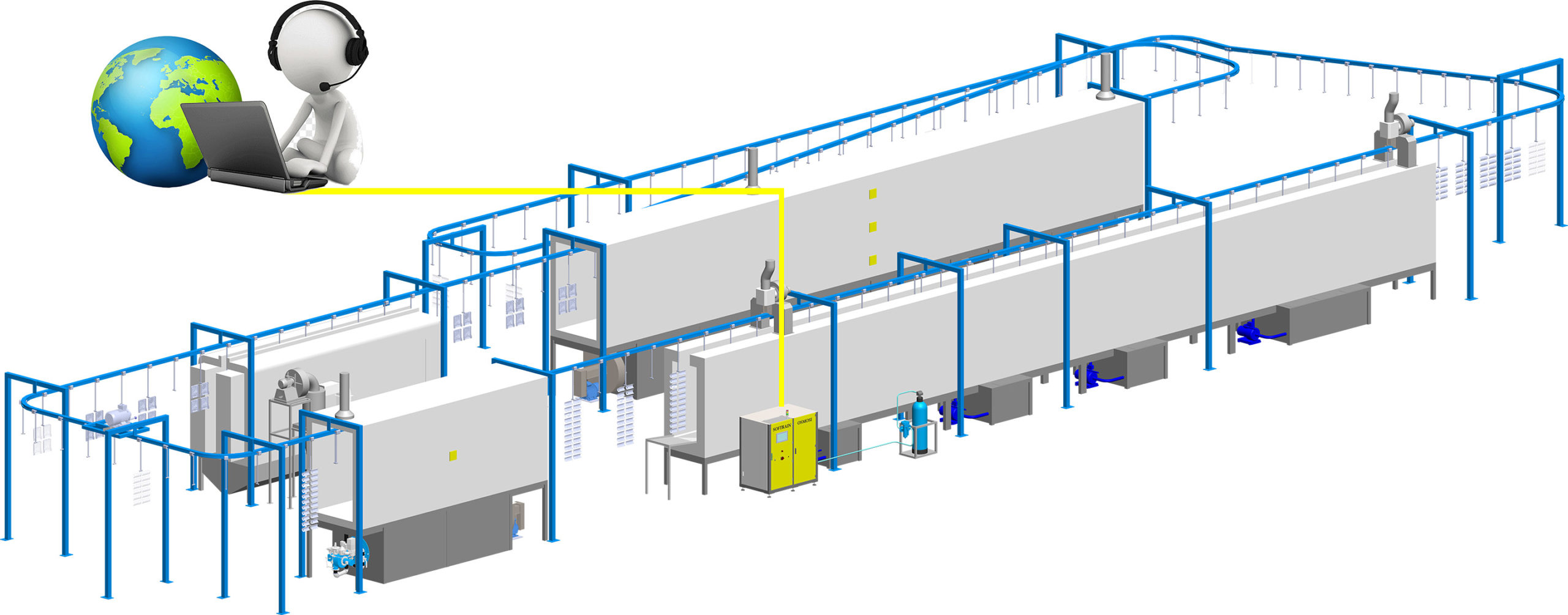

Each system that we can supply, in its standard configuration, provides the use of industrial PLCs interface connected to an operator panel that is able to support the ethernet connection.

The advantages of using remote control are many and guarantee the customer an online control service on all connected Soft Rain equipment. Access takes place using a dedicated platform where it is possible to configure different terminals or devices (smartphone, PC, tablet, etc.) and also offers the possibility of interacting, based on the type of login, with the equipment.

The Osmosi 1000 HE can be modified in the flow rate l / h and can also be implemented with dosing stations:

Soft Rain dosing stations can be used on all types of chemicals used in pre-treatment lines because they offer high chemical compatibility. The stations are completely automated and can be controlled with different methods, such as µS, pH, redox, etc.

They can be composed of one or more dosing pumps. They are equipped with the following components:

– specific electrochemical analyzers

– probes, specific electrodes for use

– dosing pumps with high chemical compatibility and with different types of flow rates in l / h, depending on the use

– suction lances for chemical product, injection valves

– transport system of the aqueous solution to be analyzed

– automatic cleaning system of the entire hydraulic circuit and therefore of the various sensors or electrodes

Depending on the type of equipment chosen, they can be installed inside the central unit (for systems) or they can be purchased as a single supply for specific use (devices).