Soft Reading

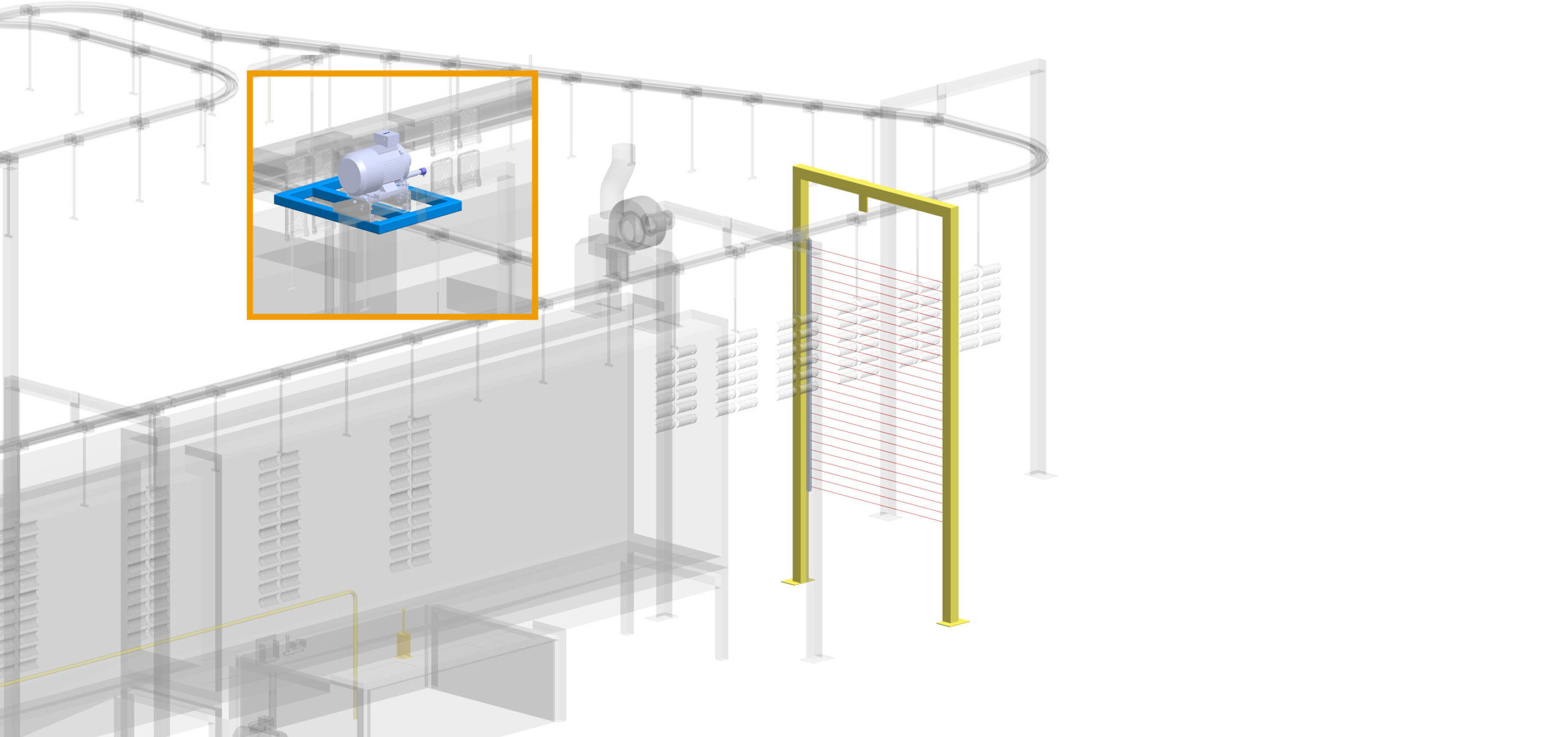

Device for reading the artefacts entering the pre-treatment tunnel.

The artifacts will be read through a pair of photoelectric barriers placed at the entrance of the tunnel and this information will allow the plant management system to optimize the pre-treatment cycles, saving the consumption of solutions and their nebulization based on the presence and geometry. of the artifact at the entrance.

The device will be equipped with:

- pair of photoelectric barriers

- aluminum structure to support the barriers anchored to the flooring

- instrumentation placed in the plant

- Management PLC for interface between barriers and the management system of the plant

- electric box with steel structure

The device can also be connected to the Internet for remote control.

Two photoelectric barriers positioned at the entrance to the pre-treatment tunnel interfaced to optimize nebulization and atomization. With an encoder installed on the chain drive unit, the incoming products will be checked.

They monitor the entry of metal products and sends signals to the central PLC which processes them by activating and deactivating the nebulization with osmotic solution and the atomization of the nanotechnological solution only when necessary.

Each system that we can supply, in its standard configuration, provides the use of industrial PLCs interface connected to an operator panel that is able to support the ethernet connection.

The advantages of using remote control are many and guarantee the customer an online control service on all connected Soft Rain equipment. Access takes place using a dedicated platform where it is possible to configure different terminals or devices (smartphone, PC, tablet, etc.) and also offers the possibility of interacting, based on the type of login, with the equipment.