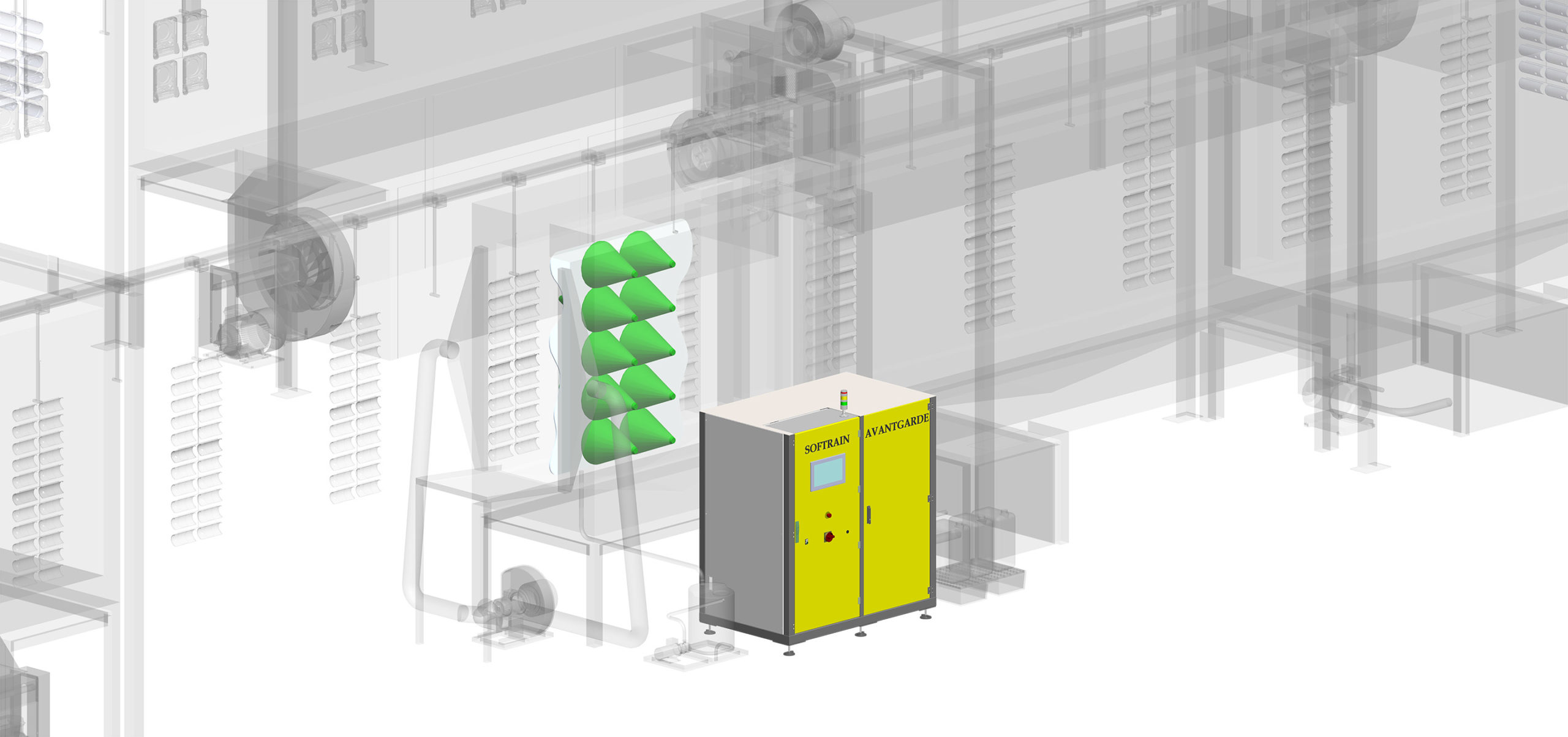

Soft Rain Avantgarde

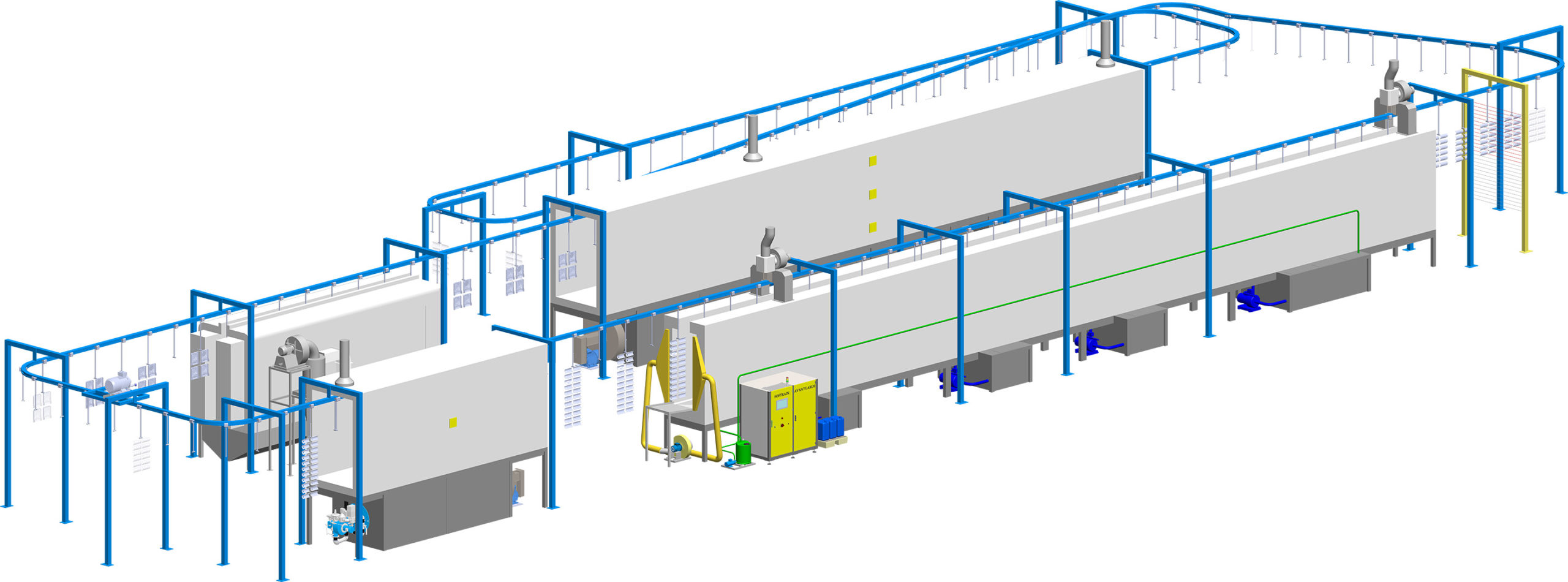

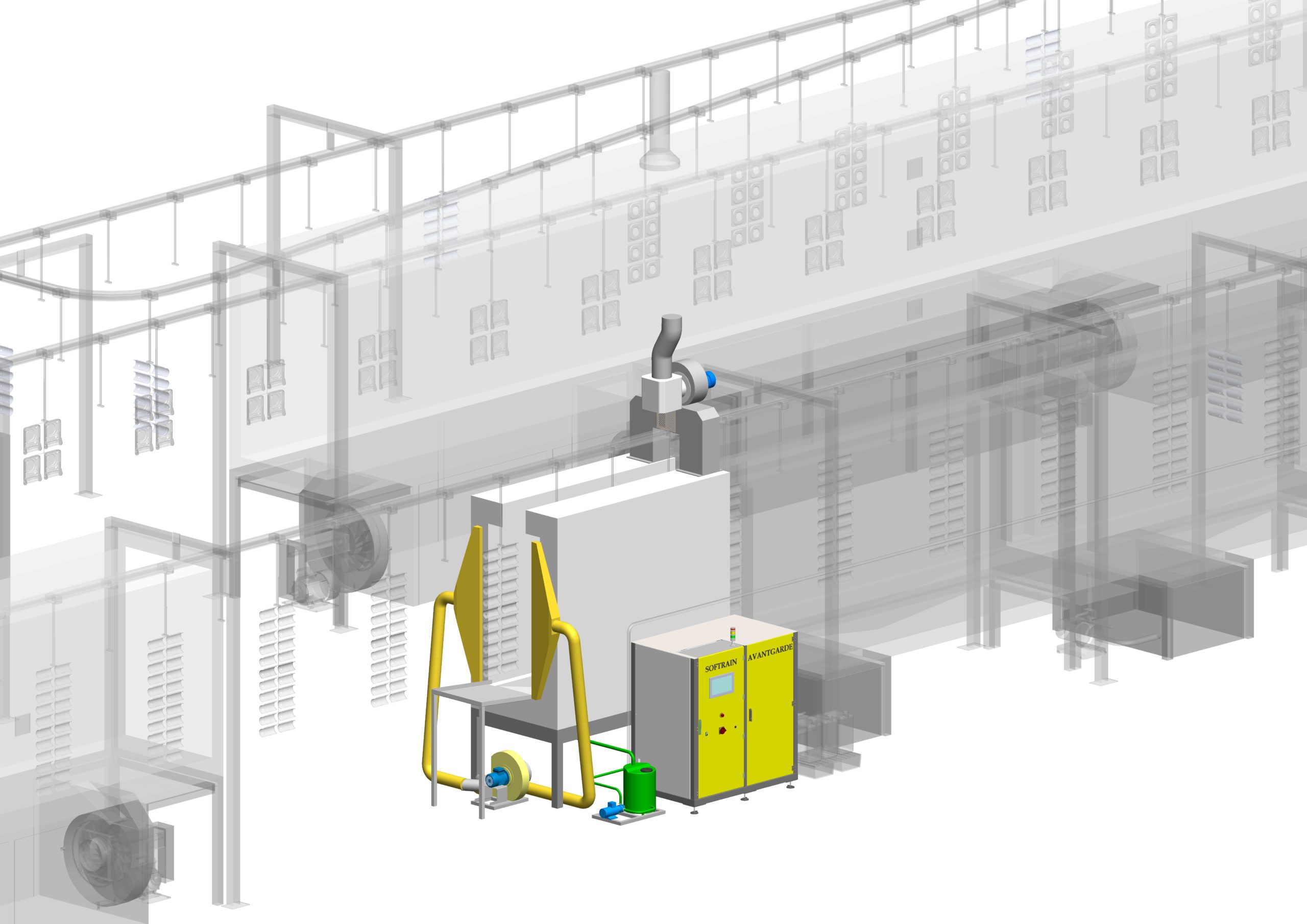

The Soft Rain Avantgarde system allows safe and automatic management to correctly apply nanotechnologies. The system is equipped with devices that allow the production of the nanotechnological solution to be always constant and free of pollutants and then apply it with high efficiency through atomization.

This system is ideal for those who already correctly perform a final rinse without hardness but intend to increase performance using nanotechnologies with constantly control of process parameters.

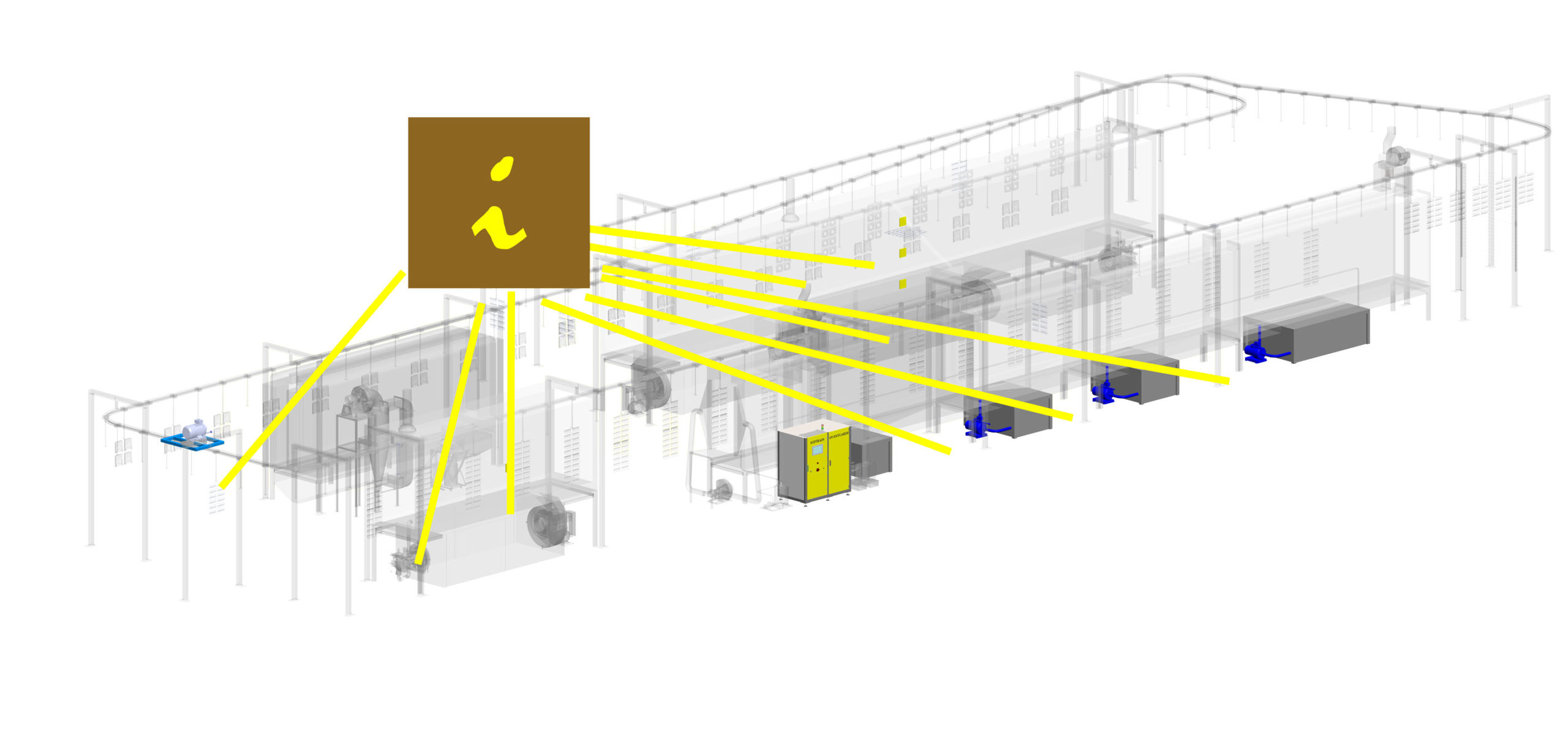

Insights into the technologies present as standard in the Soft Rain Avantgarde:

The atomization of the nanotechnology solution has been developed and patented by Soft Rain. The characteristics of the nanotechnological solution and of the particular atomization nozzles can be suitably customized for each specific installation with the aim of guaranteeing the highest quality standards on metal surfaces treated.

Nanotechnological solution always compliant with the technical data sheet of the product used. The solution applied to metal products is not subject to pollutants, as it is prepared by means of a special dedicated system as if it were prepared in a laboratory. The artifacts will always be invested by the same nanotechnological solution. Very low consumption of the nanotechnological product. Absence of defects due to a non-compliant solution. The system does not produce wastewater to be treated, the excess nebulization is recovered and used in the pretreatment tunnel process. Atomization can be applied to all products that do not require a final rinse.

If the reading of the artefacts entering the pre-treatment tunnel is associated with this application, it will be possible to accurately control the nanotechnological solution feeding.

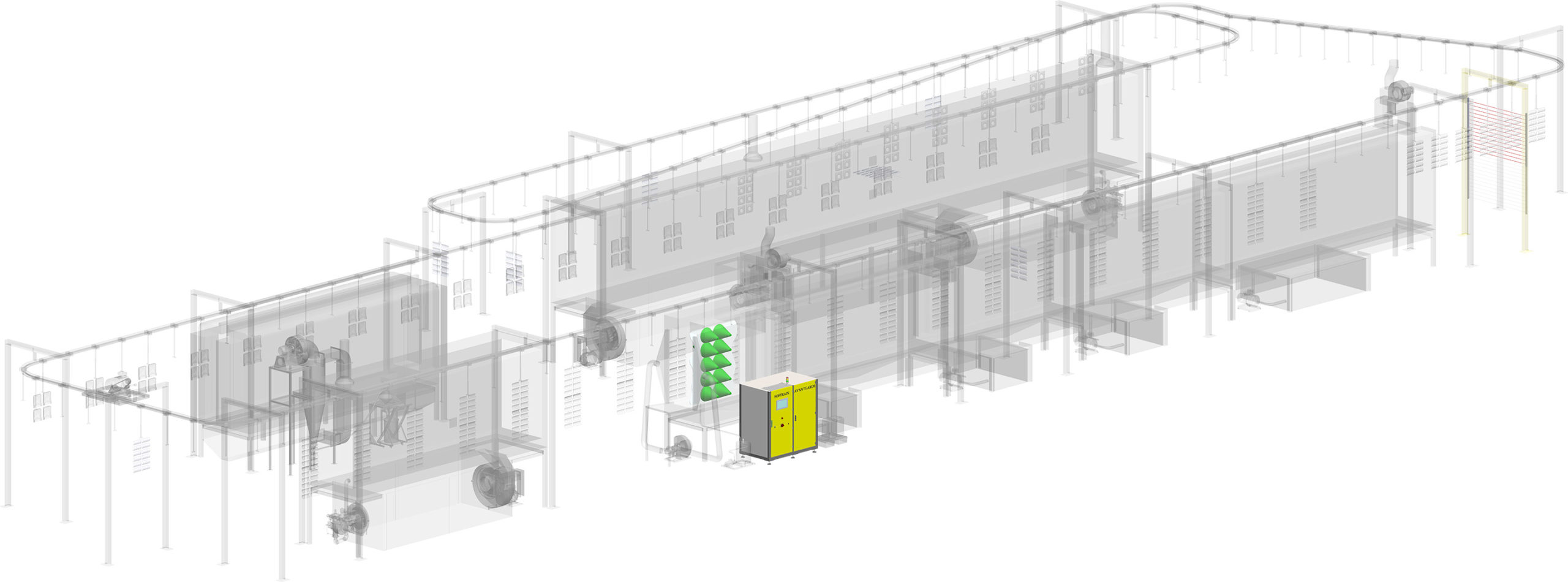

Soft Rain dosing stations can be used on all types of chemicals used in pre-treatment lines because they offer high chemical compatibility. The stations are completely automated and can be controlled with different methods, such as µS, pH, redox, etc.

They can be composed of one or more dosing pumps. They are equipped with the following components:

– specific electrochemical analyzers

– probes, specific electrodes for use

– dosing pumps with high chemical compatibility and with different types of flow rates in l / h, depending on the use

– suction lances for chemical product, injection valves

– transport system of the aqueous solution to be analyzed

– automatic cleaning system of the entire hydraulic circuit and therefore of the various sensors or electrodes

Depending on the type of equipment chosen, they can be installed inside the central unit (for systems) or they can be purchased as a single supply for specific use (devices).

This technology is provided in any system where the use of the monitoring of the parameters relating to the pre-treatment tunnel with the aim of maintaining the functionality unchanged over time.

This particular technology that equips our systems has a high importance because it ensures correct extrapolation of the data obtained from the probes and electrodes, keeping them constantly clean and thus avoiding the use of human resources for maintenance.

A software system combined with dedicated hardware make it possible to obtain the technology described above.

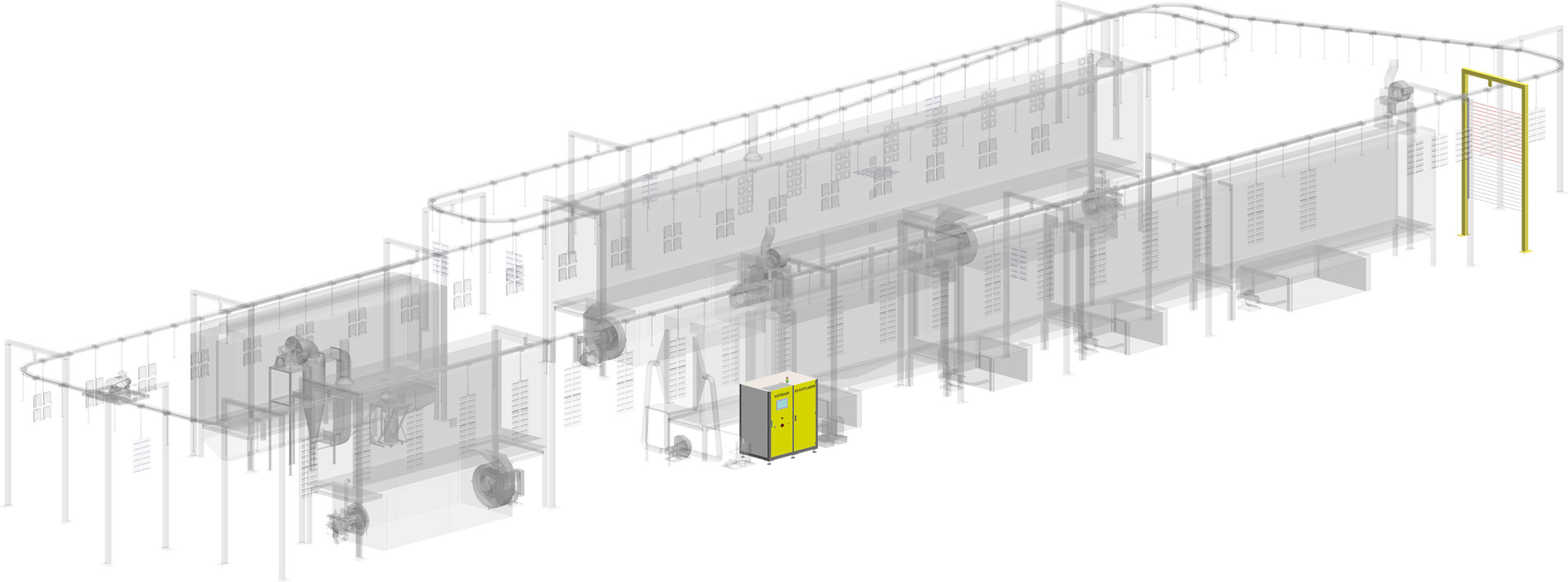

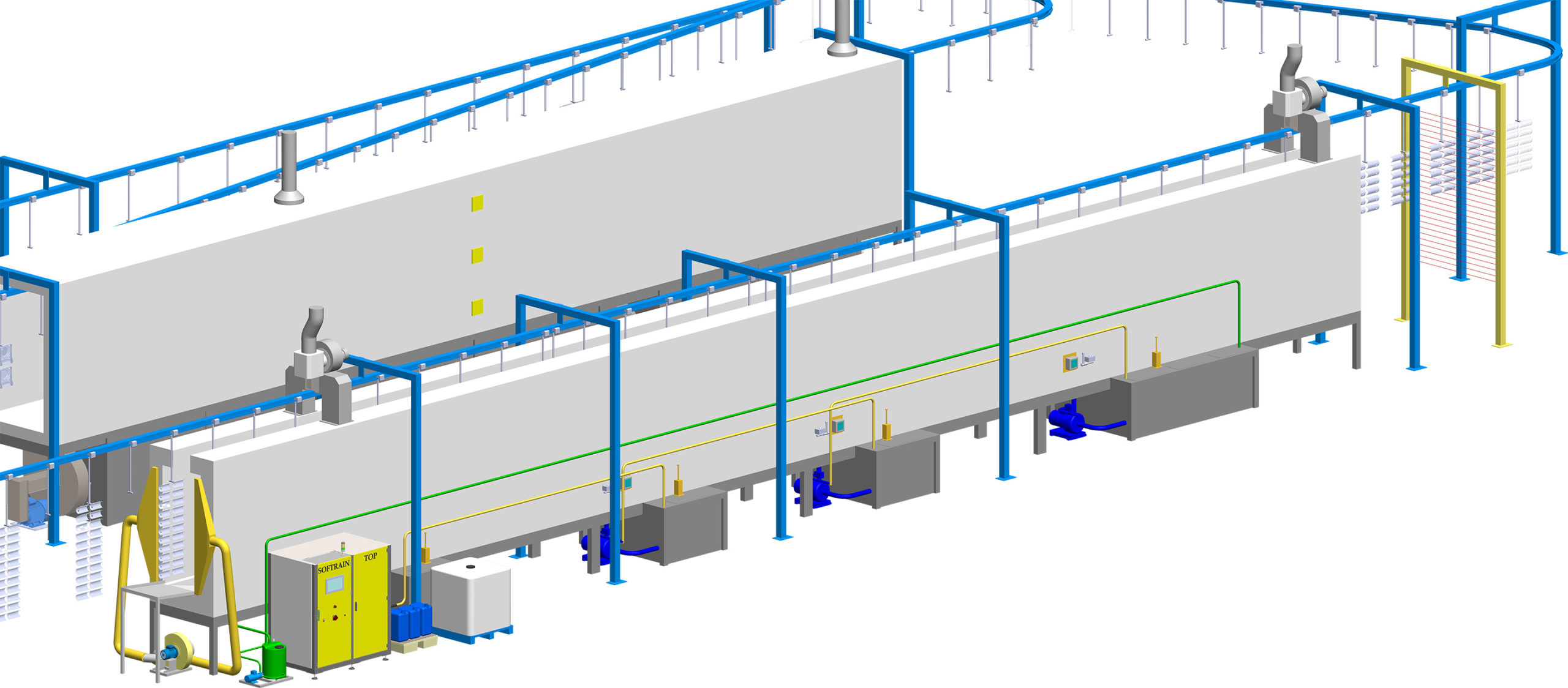

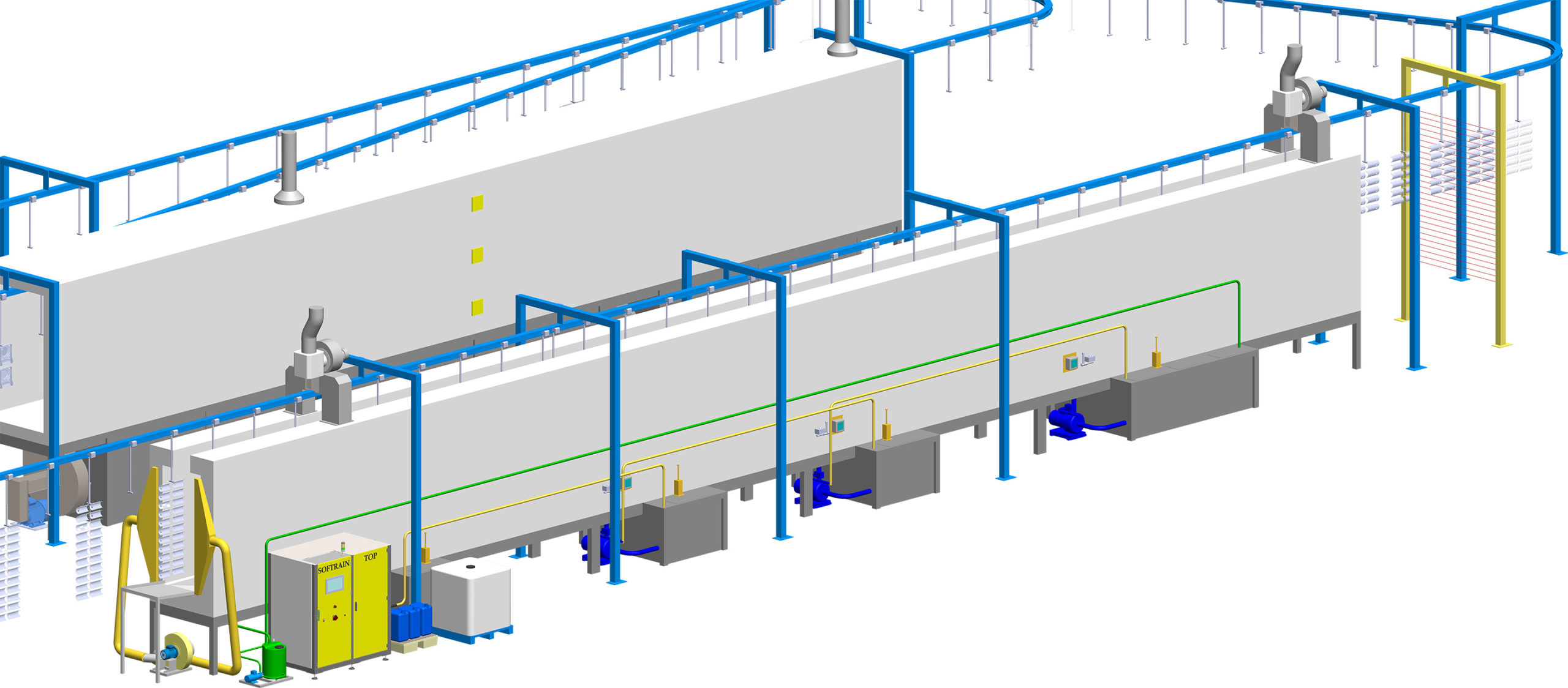

Depending on the type of tunnel, in order to correctly apply nanotechnologies, it is possible to take advantage of:

– complete application module

– forced air intake with external expulsion

– containment air blade

Metal Plast Sistemi is able to design and build custom-made stainless steel tunnel sections in order to allow the correct use of nanotechnological products. The tunnel is usually equipped with an adjustable suction by means of special throttling dampers and a forced air knife ventilation which have the purpose of confining the nanotechnological nebulization area and preventing the propagation inside the tunnel and outside.

Suction and ventilation are coordinated by the central unit if it is inserted in one of our systems.

The steel structure is self-supporting and can be made of AISI 304 and 316 stainless steel.

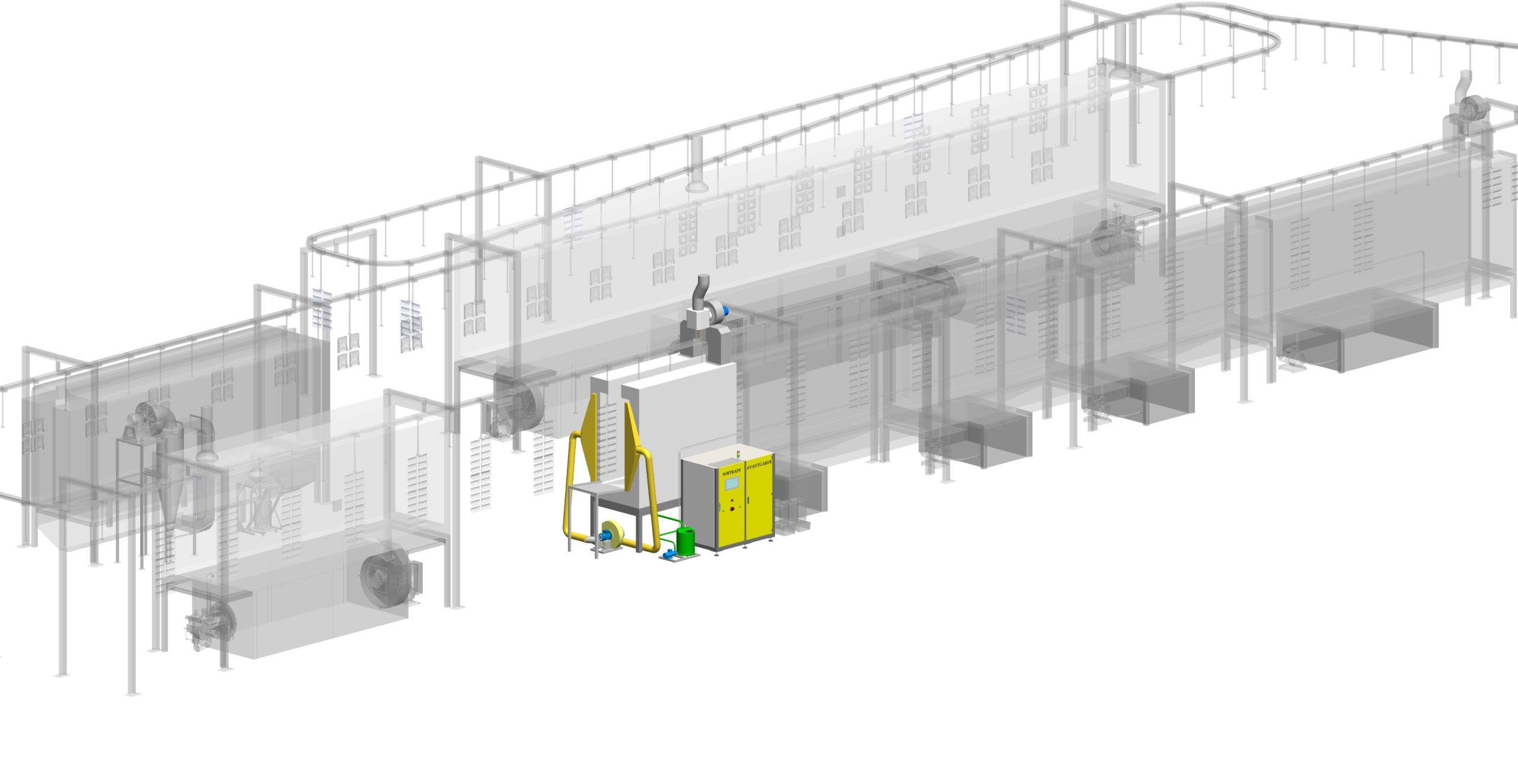

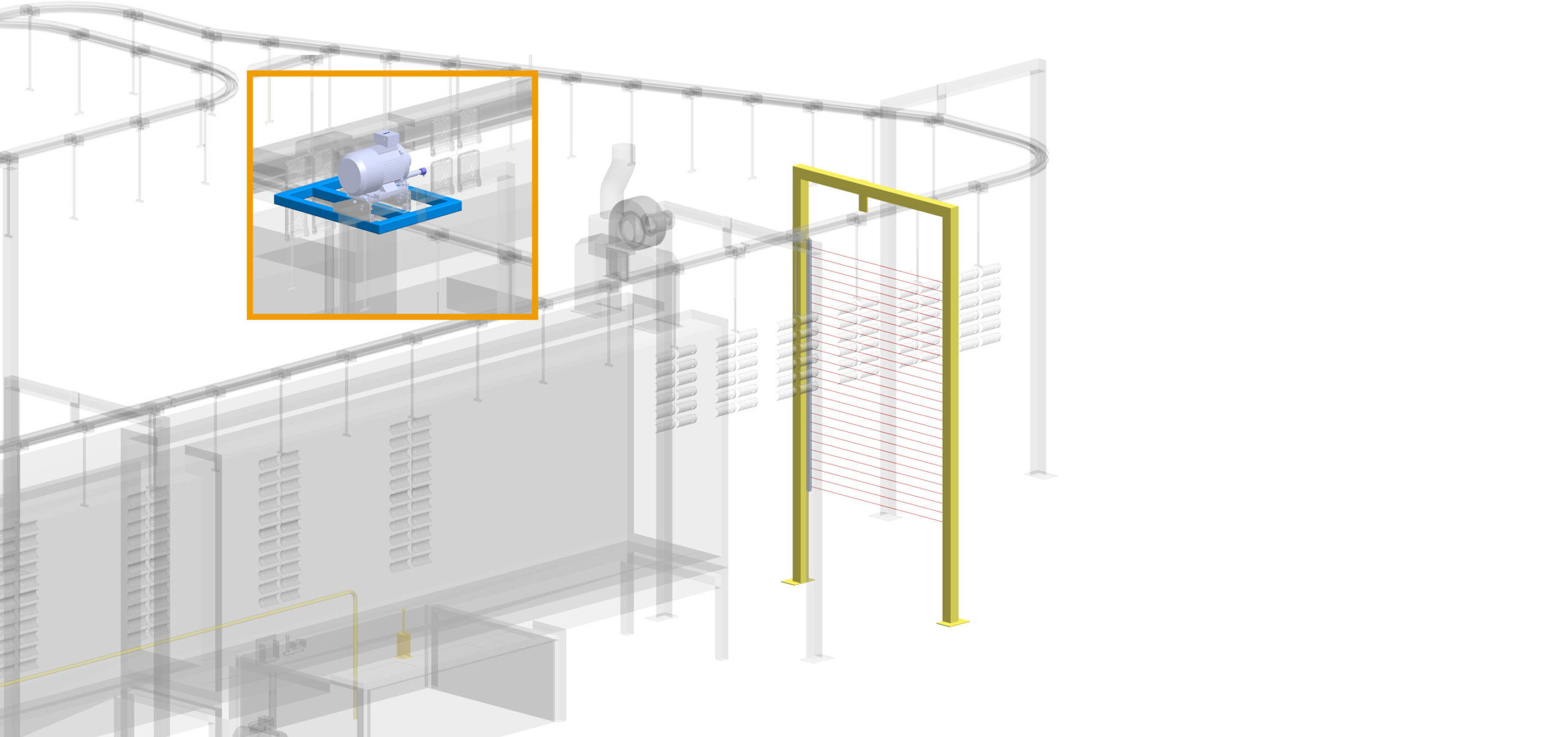

Two photoelectric barriers positioned at the entrance to the pre-treatment tunnel interfaced to optimize nebulization and atomization. With an encoder installed on the chain drive unit, the incoming products will be checked.

They monitor the entry of metal products and sends signals to the central PLC which processes them by activating and deactivating the nebulization with osmotic solution and the atomization of the nanotechnological solution only when necessary.

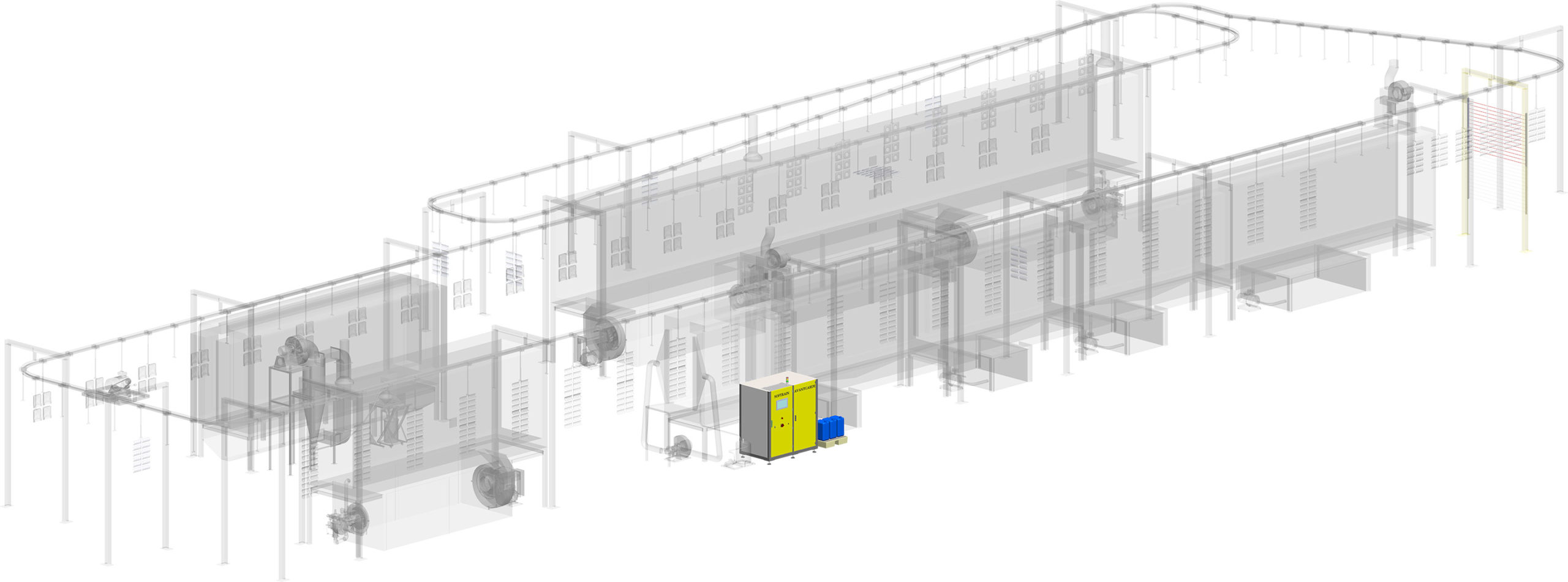

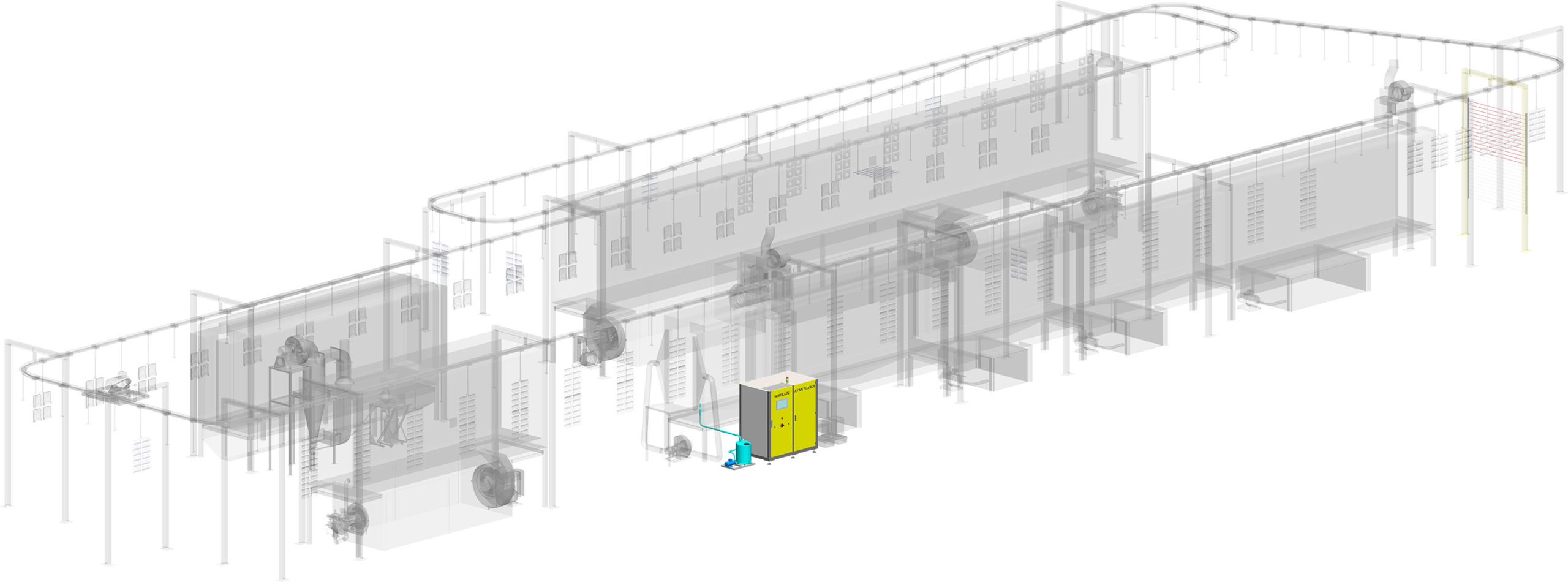

Regardless of the system chosen, Soft Rain considers the recovery and then the reuse of the nanotechnological solution by reintroducing it into the tunnel pre-treatment process.

The overspray of the excess nanotechnological solution is conveyed into a tank intended for recovery, positioned under the application module of the tunnel.

The nanotechnological solution collected inside the tank is relaunched by a pump dedicated to a tank of the pre-treatment tunnel. This operation allows to maximize the consumption of the aqueous solutions, allocating them to one of the stages of the pre-treatment process where it is allowed to use them, mixing them with the solution already present in the tank.

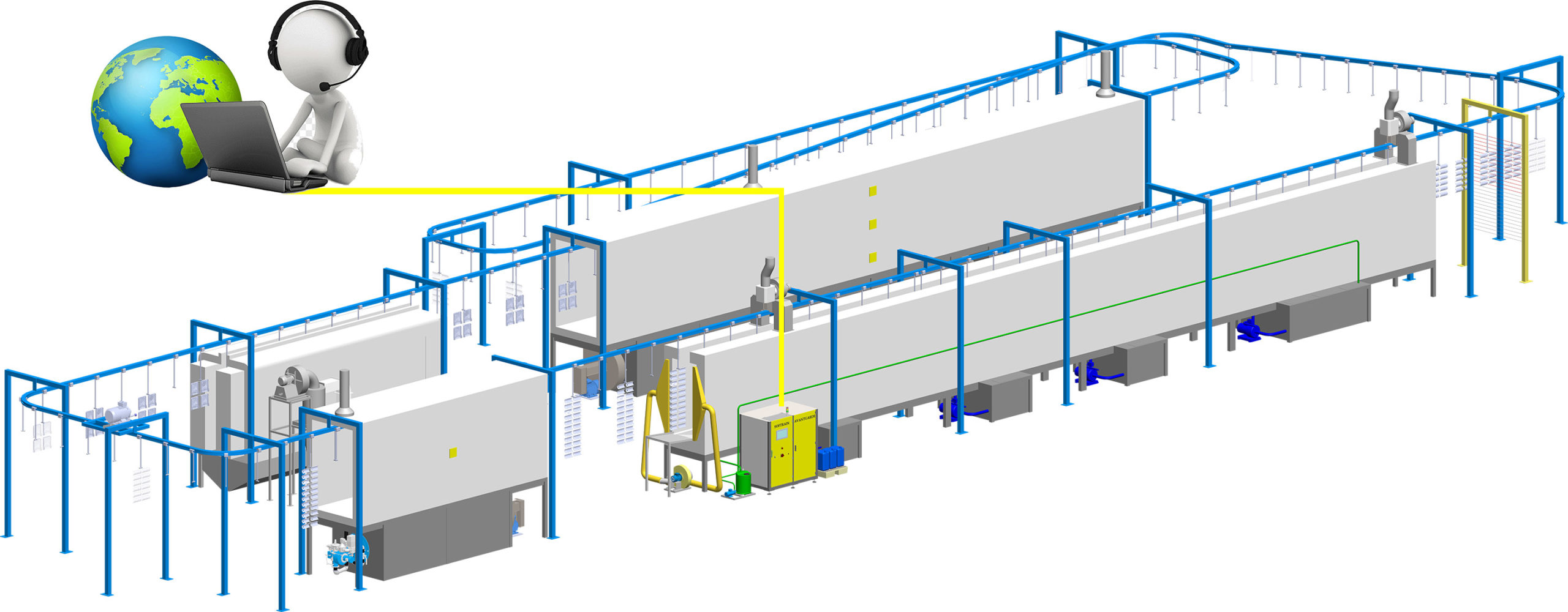

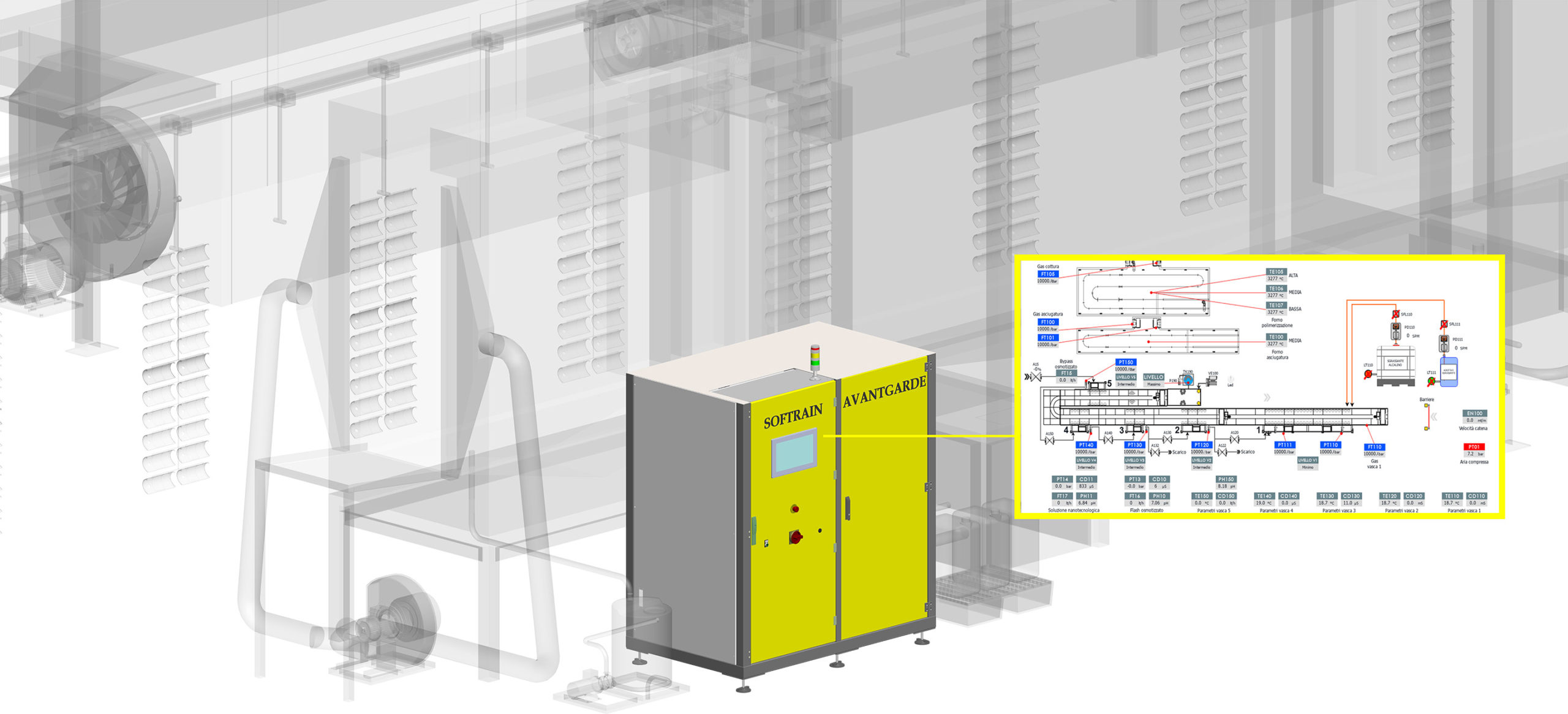

Application that controls minute by minute all the main parameters relating to the painting line, i.e. the pre-treatment tunnel, the chain drive, the polymerization oven and the drying oven.

This technology allows you to set any process alarms on the HMI operator panel and offers the possibility of recording and archiving the monitored parameters. All the necessary sensors will be installed on board the system, which interfacing with the central PLC will allow to extrapolate the required data.

The whole painting line is graphically shown on the operator panel with all the parameters obtained from the system. In a simple and intuitive way it will be possible to have a snapshot of the process conditions.

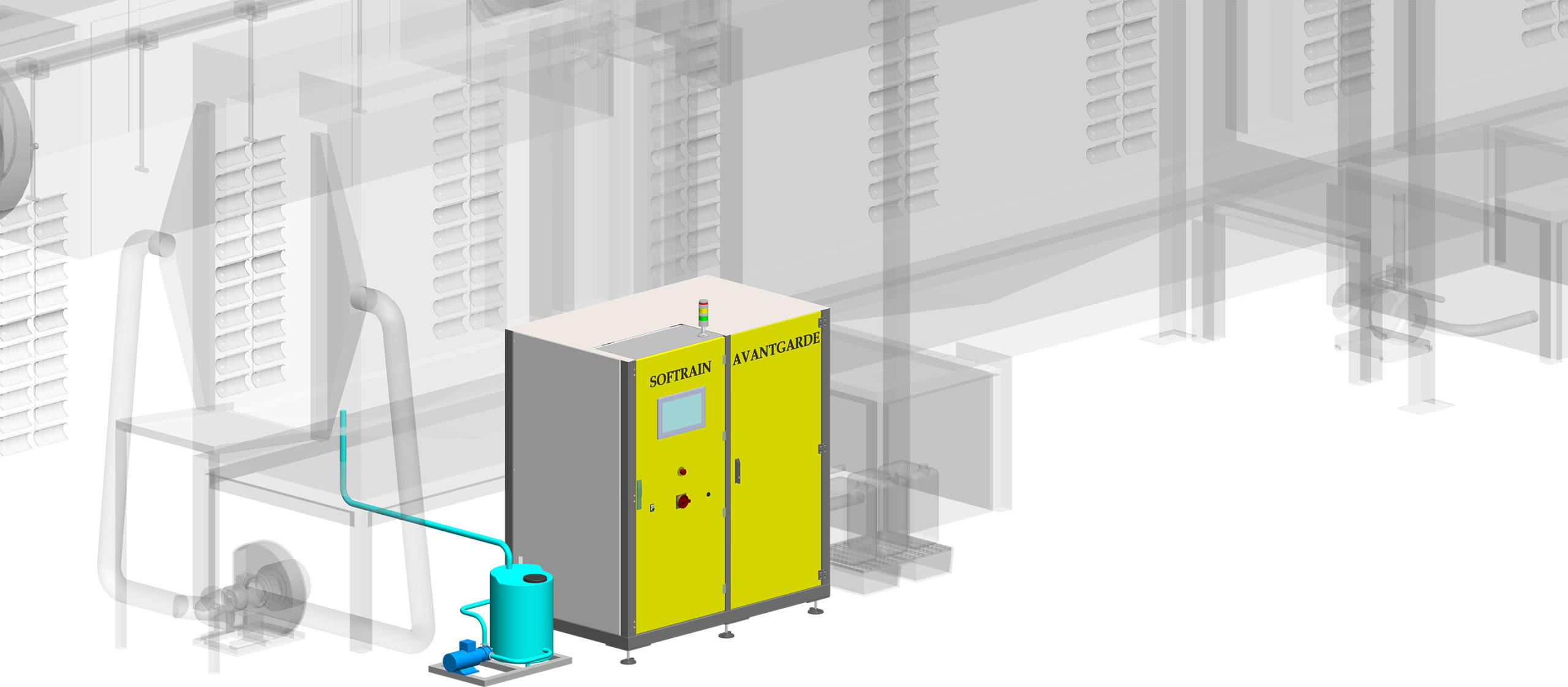

Considering the dusty environments in which the equipment is installed, the central unit was conceived and designed to contain all the components inside and keep them intact.

The central unit was designed by dividing the system into different operating areas and each one groups together the components inherent to the technology applied in it.

Electric area:

Touchscreen, simple and intuitive operator panel, in colors of 10 “, 15.6” and 17 “.

Switch emergency mushroom pushbutton for immediate stop of all activities controlled by the system.

Electrical panel with PLC, low voltage power supply and all control and management interfaces.

Electrochemical Analyzers.

Hydraulic and pneumatic areas:

Hydraulic circuit equipped with: high pressure hydraulic pumps, manual and electrically motorized valves, different types of filters, pressure regulators, flow sensors, probes, etc …

Osmotic water storage tank.

The pneumatic system is equipped with a filtering unit for the machine inlet air and uses a series of solenoid valves to drive pneumatic actuators.

All device materials are compatible with the solutions, such as PVC, PP, PVDF, PTFE, 304 and 316 stainless steel

This system is conceived and designed with PLC management devices and HMI man-machine interface to make remote control possible in teleservice.